4 Challenges of Wafer Grinding

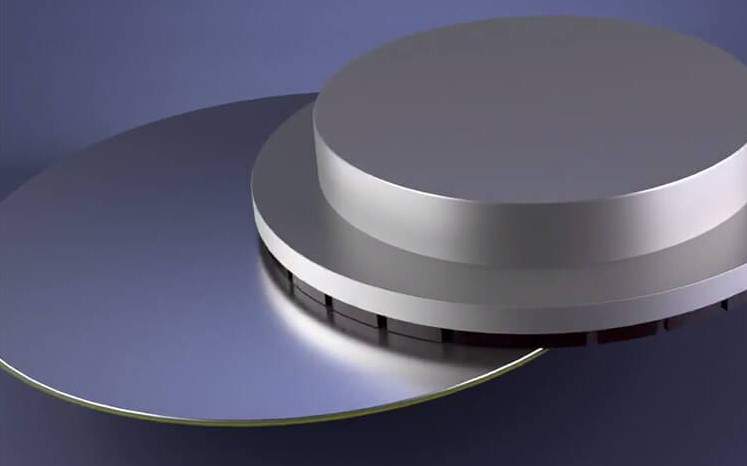

Silicon chips are becoming increasingly popular in the electronic industry. The obvious reason lies in their ability to make electronic products handy and compact while optimizing their performance. With new technological advancements and innovations, the demand for silicon wafers is on the rise. Power semiconductor components consume less power and produce less heat because of the sophisticated conversion. To cope with the increased demand, semiconductor manufacturers have shifted towards thin wafers.

Silicon wafers have a thickness from 50 to 100 µm, however semiconductor manufacturers aim at reducing the size of these wafers even more. They are targeting to make wafers as thin as 1 µm with the help of mechanical polishing. This polishing is done at the back of wafers. Although this helps in reducing the thickness and size of the wafer, there are downsides to this practice. In this article, we have discussed 5 challenges of making silicon wafers thin through grinding.

1. Grinding marks

Wafer grinding is done to reduce the thickness and improve the surface quality of a wafer. The technique of wafer grinding exists to minimize lapping and polishing practices. The sliced wafer undergoes a grinding operation for smoothening the waviness and to ensure that the front and the back surface remain parallel. Furthermore, with after the completion of circuits on the front, backgrounding is required for finishing purposes. Wafer grinding can however lead to the generation of grinding marks. These are striations on the wafer that can affect the performance and quality of wafers. The quality of a wafer relies on the depth and pattern of the marks. The orientation of the grinding marks differs from one dice to another and determines the strength of the wafer. You can optimize the surface quality and the dice strength by thoroughly understanding the process of wafer grinding. This can help you identify the pattern of grinding marks and eventually resolve the problem.

2. Grinding failures and edge chips

During wafer grinding with the help of diamond, various complications can arise. Diamond grinding is preferred because of its consistent quality and accuracy. However, due to extra thinning of the wafer and residual stress, the wafer can break along the edges known as edge chipping. To ensure the strength of a wafer, the edges of the wafer are rounded. At times these edges can become extremely sharp during the grinding process, affecting the strength and durability of the wafer. The thin sharp edge can chip off resulting in bad wafers.

3. Star Cracks and Comets

Wafer grinding is carried out on a grinding wheel i-e resin-bond diamond cup wheels. The wafer is held upon this wheel. Both the axes of rotation for the grinding wheel and wafer are offset at a distance. This leads to the formation of a conic shape. The conic shape of the grinder results in the formation of a cone or star-shaped wafer. During wafer grinding, small cracks can appear along with the conic processing. These are known as star cracks or comets.

Star cracks can be controlled by controlling cone formation. To achieve this wafer manufacturers have to adjust the rotation angle between the wheel axis and the wafer axis. The bigger the angle of the axis, the more conical the shape is, and vice versa.

4. Cleavage lines

Wafer grinding involves the process of cleaving. It starts with a diamond scratching or scribing the wafer surface to mark the points for cleaving. Once the points are marked, dicing becomes easier, more defined, and more accurate. A controlled fracture can be induced along the lines of scratches. There are two ways of performing cleaving. However, these procedures can sometimes fail to produce cleaves normal to each other, or trigger unwanted fissures along the cleavage lines. These cleavage lines act as points of vulnerability.

Conclusion

Every practice has an upside as well as a downside. To make silicon wafers thin to cope with their availability, silicon wafers face certain challenges. Wafer grinding affects the functionality of wafers which ultimately impacts the performance of gadgets in which it is deployed. Some of the commonly experienced problems of wafer grinding have been discussed in this article.

Die Prep Services is a reliable manufacturer of silicon wafers. For trustworthy products and services in Silicon Valley, visit our products/services page.