Sustainable Vehicle Recycling: Eco Systems Advancing

What happens when today’s cars reach the end of their lifecycle? For years, the answer was simple: strip them for parts, scrap the leftovers, and call it a day. But as vehicles become increasingly complex (e.g., hybrids and EV batteries), the old ways of recycling just don’t cut it anymore. With environmental issues and insane demands of sustainability, the question becomes a bit more difficult. How do we recycle cars effectively without adding more issues than solutions?

The good news is that innovation is stepping up to the challenge. From AI-powered sorting systems to smarter material choices, the automotive industry is rewriting the rules of vehicle recycling innovations. These developments are not merely making production processes more eco-friendly but setting the path to a second life of some materials such as EV batteries.

Want to know how these breakthroughs are reshaping the future of car recycling? Just keep scrolling as we discuss the latest tech trends, processes, and sustainability strategies. Trust me—there’s a lot worth talking about.

Current Vehicle Recycling Statistics

The automotive industry is already one of the major leaders in recycling. The most recycled consumer item is autos, where 95% of the retired passenger vehicles are recycled annually. This efficiency implies that about 86% of the material content of a vehicle (steel, aluminum, fluids, and floor mats) is recycled, reused, or energy recovered.

Nevertheless, there are still major obstacles to overcome, especially on plastics. An average car of today may include 240 kg of plastic, which comprises 14-18% of its weight. Despite sustainability commitments, less than 20% of these plastics are currently recycled. In Europe, this results in over 800,000 metric tons of plastic from end-of-life vehicles (ELVs) being sent to landfills or incinerators annually, representing a major environmental burden and a lost economic opportunity.

Innovations Driving Sustainable Vehicle Recycling

To tackle the “tough-to-recycle” materials and build a true circular economy, the industry is investing heavily in new technologies.

A. Advanced Material Separation Technology

The initial problem is the difficulty of sorting an assortment of materials in a modern car. Traditional ways of dismantling were sluggish, manual, and ineffective. Now technology is making it a quicker, safer, and more accurate procedure.

➜ Automation: Robotic arms and advanced machinery can now disassemble vehicles with incredible precision, separating parts much faster than humans. A case in point is BMW Group, which is working on a project alongside AI and robots to optimize the post-shredding dismantling process to increase the purity of recovered materials such as aluminum, steel, and plastic.

➜ Advanced Sorting: Recyclers now use a suite of high-tech tools to separate materials. These involve magnetic separation of steel and aluminum using the eddy current separation and optical sorting systems, or infrared sensors capable of detecting the various types of plastic.

➜ Chemical Recycling: In case of mixed or degraded plastics that cannot be sorted using mechanical methods, chemical recycling is an innovation. The process decomposes plastics into their molecular building blocks and can be used to make them into virgin-quality polymers that are used in new products.

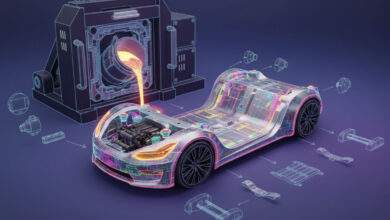

B. Electric Vehicle (EV) Battery Recycling

The shift to electric vehicles (EVs) solves one environmental problem (emissions) but creates a new recycling challenge (the battery). EV batteries are massive and are full of valuable, dangerous, and difficult-to-extract resources such as lithium, cobalt, and nickel.

A “three-pillar” strategy is emerging for these batteries:

♻️ Reuse: Refurbishing battery packs by replacing worn components and re-certifying them to original equipment manufacturer (OEM) specifications for use in another vehicle.

♻️ Repurpose: Giving the battery a “second life”. Once a battery is no longer suitable in a car, it can be used for other purposes, including those of energy storage in homes.

♻️ Recycle: Treating the battery to recover the maximum amount of raw materials.

C. Bio-based Materials in Automotive Design

A key part of the solution is sustainable car design. Manufacturers are substituting conventional materials with sustainable materials that are simpler to process.

This includes using bio-based plastics derived from renewable resources like sugarcane and cornstarch. There is also an increase in the use of natural fibers like hemp, bamboo, and flax as components of interiors. Such materials are biodegradable and can be more easily recycled.

However, this is a complex technical challenge. Other manufacturers are incorporating polymers with natural fibers to enhance performance, but these materials cannot be recycled using conventional methods. This highlights the need for a holistic design approach.

D. Circular Economy Systems for Auto Parts

The ultimate goal is a “circular economy“—a closed-loop system where waste is eliminated and materials are continuously reused.

There are three foundations on which this system is being constructed:

- Design for Disassembly: Some of the manufacturers are designing their products with standardized fasteners such as clips and bolts rather than permanent welds. They are also introducing modular features (e.g., battery packs that can be easily removed) to make recycling much easier.

- Digital Tracking: Technology provides the transparency needed for a true circular economy. Digital tracking systems can follow a car through the entire recycling process, recording what materials are recovered and where parts are sent. Europe is mandating this with its digital “battery passport“ requirement, which takes effect in 2027. Such a passport will specify the composition of a battery, its carbon footprint, and how it can be repaired.

- Collaboration: No single company can do this alone. Initiatives like the Global Impact Coalition (GIC) Automotive Plastics Circularity project bring together chemical companies (like BASF and Covestro) and dismantlers. They are testing new ways to sort plastics at the dismantling stage to improve the quality and value of the recycled material.

Benefits of Sustainable Vehicle Recycling

The push for better recycling is driven by clear advantages that span our economy, environment, and society.

➜ Economic Benefits: Recycling of materials will result in a tremendous reduction in the energy and costs incurred in the extraction of the raw materials. For instance, recycling aluminum saves up to 95% of the energy required to produce it from raw bauxite. The industry also generates jobs and sustains more than 100,000 employees in the US alone and earns billions of dollars annually from recycled materials and salvaged parts.

➜ Environmental Benefits: This is the most obvious win. Recycling curbs the dumping of tons of materials (i.e., rubber, glass, and electronics) into landfills. The huge energy savings translate directly to reduction in greenhouse gas emissions. It also conserves finite resources, reducing strain on materials such as iron ore and lithium.

➜ Social Benefits: The best companies in the field of recycling improve their image and show their sense of ethical behavior. Many recycling projects also foster community involvement through local projects or charities.

MORE ON AUTOMOTIVE INNOVATION

Auto Insights 2025: Revolutionizing Business Processes

Challenges in Recyclable Vehicle Design

If the benefits are so great, why isn’t every car 100% recycled? Well, technical and economic barriers are also high in the industry.

A. Complexity of Modern Vehicles

Modern cars are incredibly complex. Advanced electronics, intricate designs, and the use of mixed materials make dismantling very difficult. Plastics are often contaminated, mixed, or degraded after a decade of use, making them hard to sort. The industry’s increasing use of composite materials, which are lightweight and strong, also creates a recycling dead-end, as many are unsuitable for conventional recycling.

B. Cost Barrier

This is perhaps the biggest hurdle: economics. Unlike metals, which have high value, recycling plastics from ELVs is currently more costly than using virgin materials. Sustainable materials and greener alternatives are also more expensive for manufacturers to purchase. This creates a market imbalance where recyclers emphasize high-value metal recovery over low-value plastic.

A landmark 2021 World Economic Forum and Boston Consulting Group report, “Net-Zero Challenge: The Supply Chain Opportunity,” analyzed this problem. It found that fully decarbonizing a mid-size car would increase its total cost by less than 2%. However, this is only true if the cost is distributed across the entire value chain. If the burden falls on upstream producers, the report notes that steel prices alone could rise by nearly 40%, straining the lowest-margin stage of the process.

C. Lack of Standardization

Every car manufacturer does things differently. Universal recycling systems are hard to establish because proprietary components are used. This is compounded by regulatory barriers, such as differences in waste management frameworks and recycling infrastructure between EU member states. There are even “cultural barriers,” where a lack of information sharing due to concerns over competitive advantage hinders progress.

Future Outlook for Vehicle Recycling

Despite these challenges, the future of vehicle recycling is exciting. We are moving toward a future in which fully recyclable, disassembly-designed vehicles become standard.

With Artificial Intelligence (AI), automation and robotics will enable recycling to be much more efficient. Data analytics will enable recyclers to optimize their processes, whereas AI systems will be able to forecast the demand for specific materials. Advanced chemical recycling technologies will evolve to handle the materials that are currently considered unrecoverable.

It is even possible that 3D printing will be able to revolutionize the process. In the future, it is possible to imagine recycling old cars and printing the raw materials in a 3D printer to create additional eco-friendly car parts and save so much waste. Now that sounds pretty amazing, doesn’t it?

The automobile sector is at a critical juncture.

Seeing the evolution from a linear “take-make-dispose” model to a circular one is not just an environmental necessity but a powerful economic opportunity. While technology drives much of this change, human leadership and consistency remain the foundation of success. As discussed in a Service Department Roundtable, core principles like accountability and culture never go out of style, whether you’re improving a service drive or revolutionizing an entire industry’s approach to waste. Through circular design and innovation, the automotive industry can make the first step to a world where nothing is wasted.

Is Your Dealership Ready for the Future?

As the automotive industry evolves, so must dealership operations. With new car sales facing uncertainty, many people are keeping their vehicles longer. This shift makes your fixed operations more critical than ever. Cars will always need service and repairs, creating a stable and profitable revenue stream that can save your dealership.

Chris Collins Inc. specializes in transforming service departments into high-performing profit centers. Led by Chris Collins, our team provides leadership and accountability coaching designed to skyrocket your customer satisfaction, retention, and profits. We offer a wide range of services—from on-demand training to our Signature Coaching Group—to give your team the systems they need to succeed.

Don’t let your dealership’s most valuable asset underperform. Book a 15-minute strategy session with our team to unlock your service drive’s true potential.

Conclusion

Indeed, vehicle recycling innovations aren’t just about transforming junk into treasure—they’re paving the way for a greener, smarter future we can all be proud of. The possibilities are exciting (and much needed), whether it is high-tech solutions that transform old cars into valuable assets or breaking the circular economy in which materials are kept in flow. So, why not spread the word? Share this article with friends or colleagues, and together, we can drive the conversation forward. After all, the road to a sustainable automotive world starts with us—let’s shift gears and make it happen!

—

Author: Maverick Steel is a writer and digital marketer who enjoys connecting the dots for strategy and engaging content. He spent 6 years in secondary education as a proud campus journalist, specializing in editorial and column writing. Holding a bachelor’s degree in Marketing Management, Maverick is also a devoted advocate for positive cyber citizenship and a certified pet lover. When he’s not busy writing, you can catch him hitting the gym or enjoying a matcha latte at the nearest aesthetic coffee shop.